Click on the follow link to find out more information: https://www.jxconveyor.com/conveyor-rollers/

Company Info

- Company Name: Hebei Juxin Conveyor Engineering Co., Ltd

- Representative: lifajun

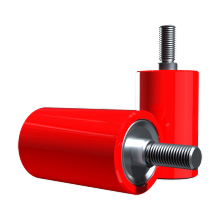

- Product/Service: Belt Conveyer , Conveyor Rollers , Conveyor Idlers , Conveyor Frames , Conveyor Pulley , Conveyor Belt Cleaner

- Capital (Million US $): ninety-six million

- Year Established: 2003

- Total Annual Sales Volume (Million US $): US$50 Million - US$100 Million

- Export Percentage: 31% - 40%

- Total Annual Purchase Volume (Million US $): US$10 Million - US$50 Million

- No. of Production Lines: 6

- No. of R&D Staff: 31 -40 People

- No. of QC Staff: 11 -20 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 50,000-100,000 square meters

- Factory Location: Cuizhuang Industrial Zone, Zaoqiang County, Hengshui City, Hebei Province,China

- Contact Person: Mr. wanglei

- Tel: +86-0318-8438222

Premium Related Products

Hot Products

Slewing Ring Swing Bearing with Gear Hardness GradientHigh Precision Chrome Steel Pillow Block Bearings Ucp207Stainless Steel Square Shape Four Bores Bearing BlockCompetitive Price and High Quality Aligning Ball BearingHot Sale Good Quality Thrust BearingHigh Precision Large Size BearingLow Price Self Aligning Ball Bearing SlideAngular Contact Ball Bearing For Ceiling Fan Chrome SteelDouble Trust Ball Bearing PriceHigh Precision transmission roller bearing saleChina high precision Axle Sleeve PromotionMan truck Bearing PriceWheel Hub Bearing Type needle roller bearingDeep Groove Ball Bearing & Ball Bearing & Bearing Made in ChinaHot Sale Low Price High Quality Pillow Block Ball Bearings With Housing UCC328 300*145*59mmHot Sale Low Price High Quality Wheel Hub Bearing 47KIWD02 Car Auto parts