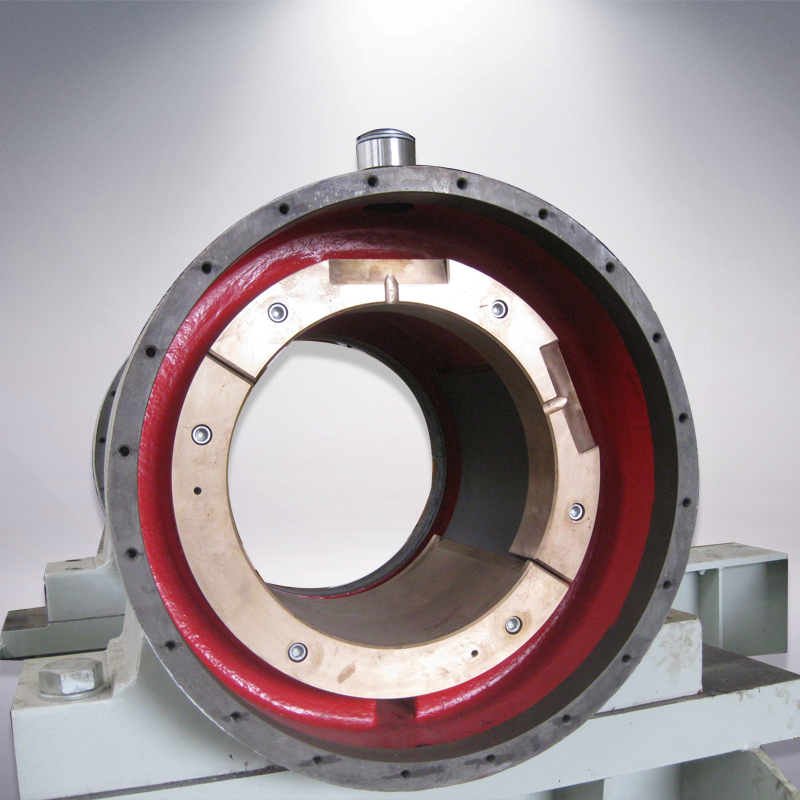

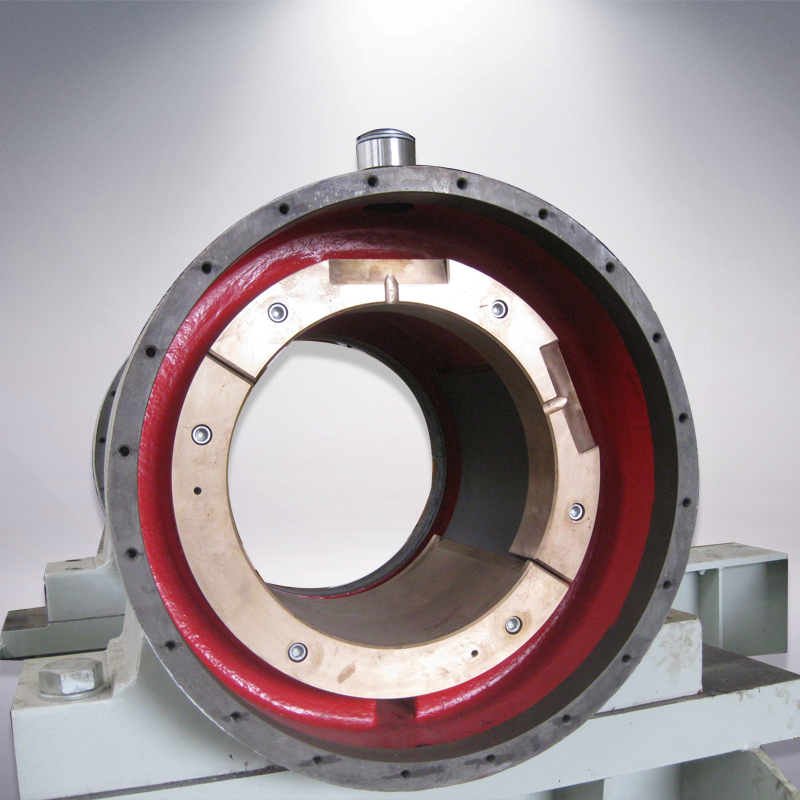

Bearing Sleeves For paper making

Basic Info

Model No.: YYD-002

Product Description

There are two main types of wear sleeves. The most common type is a thin walled metal sleeve that slides onto a shaft and is placed over a worn or marred section of a shaft that a seal rides on. The wear sleeve covers the shaft imperfection and allows the end user to utilize the same shaft sized seal in the application. Wear sleeves eliminate the need for an end user to have to purchase a new shaft or have a special size seal manufactured to adjust to the marred shaft. Thin walled wear sleeves are often referred to as [Speedy" sleeves in industrial applications. Wear sleeves are available for numerous standard inch and metric shaft sizes.

The other type of wear sleeve is thicker and is utilized in applications where thinner [speedy sleeves" are not available. Made to order wear sleeves are designed to be utilized in severe applications with larger shafts sizes such as rolling, metal, mineral or chemical plants. Unlike the thinner walled [speedy" sleeves that are installed after a shaft is damaged, it is recommended that the thicker wear sleeves are utilized on applications from the outset, as since they are made to size, downtime can be minimized and seal size can be standardized.

We also has another production line which specializes in the forging and precision machining of

many kinds of Bearings, bushings, axes, flanges,hubs,cylinder liners etc. Our products are exported

worldwide and we supply the wear parts for world leading companies in the Minging and Metal

Recycling industry.

Quality guaranteed.

Competitive Price as a manufacturer base.

Response as quick, correct.

Delivery as easy, cheapest, world-wide.

If you are interested, We can manufacture spare parts according with customer's drawings.

Copper alloy is made of pure copper after adding alloying elements, commonly used alloying elements for zinc, tin, lead, manganese, iron, aluminum, titanium, etc.As alloying element of solid solution strengthening and second phase strengthening, made of copper alloy can not only improve the strength, and maintain the characteristics of the pure copper, and thus has been widely used in mechanical industry.

Casting of copper alloy with excellent casting performance and high mechanical properties, good machinability, weldability and corrosion resistance, has a tendency to stress cracking.Generally applicable Yu Falan, seat, nut, etc., the general structure, ship, instrument appearance, simple casting using such as sleeve, sleeve, bearings, etc., in the air, water, steam, oil and fuel working environments, such as work, wear resistance, corrosion resistance good general purpose such as shaft sleeve, gear, etc.

FAQ

1.Q: What products do you offer?

A: Shenyang YYD Casting provides parts are tailored with your requirements. It ranges mainly from METSO crusher parts, especially HP series, totally replacement parts, we also welcome OEM offer from you.

2. Q: What materials can you make?

A: Tin-copper bronze, Aluminum-copper bronze, Zinc-copper bronze, Manganese-copper bronze and other material according to customer provided.

3. Q: How about the capacity? What is the max dimension?

A: The capacity is 30 tons per month. The max dimension we have casted is 5meter.

4. Q: What information should we provide to you to confirm our order of parts?

A: For standard part, you only need to provide the part number than we will define the part. But others, you should provide the technical drawings of your parts.

5. Q: What's the after-sales service if your product has quality problem?

A: First of all, you should provide us photos of the problem part and machine then our engineers will collect the necessary information to find the root cause. If it's indeed a quality problem of the product itself, we must afford compensation to you and also figure out solutions to avoid the same problem. However if it's caused by client's misconduct, we also provide the technical suggestions for our clients to solve problem better.

6. Q: Can we visit your factory?

A: Yes, of course, welcome to our factory in workday and our sales team will show you everything you want to know.

Product Categories : Bearing Sleeves For Paper Machine